SHENG ZHENG XING NENG PLASTIC CO LTD

Website:www.xnsujiao.com.cn

Phone:0086+0755-15712136850.

E-MAIL:xnsujiao@foxmail.com

ADD:Huaning road,dalang longhua district,4th Shen zheng Guangdong CHINA

- Author:

- Source:

- Date: 2021-03-13

- Views: 1311Times

The stacking height of the goods stored in the warehouse is related to the following factors:

The stacking height of the goods stored in the warehouse is related to the following factors:1. Ground load-bearing

In the design stage of each warehouse, the design institute will give a maximum load per square meter. At present, the more common ones on the market are 3-5 tons. Some warehouses for storing steel have a larger floor load, and some can reach more than 10 tons. In other words, the carrying capacity per square meter of the goods we store cannot exceed the design capacity.

The design index of ground load-bearing usually comes from the requirements given by the property right unit (owner). That is to say, the property right unit usually locates the main customer groups of the future warehouse when designing the warehouse. For example, for customers in the fast-moving category, there is no need to design a load-bearing capacity of 10 tons per square meter, because this operation is obviously a waste of resources.

In addition, the load-bearing capacity of the ground is also closely related to the cost of the warehouse. The load-bearing capacity of 10 tons per square meter and the load-bearing capacity of 5 tons per square meter are only twice the relationship, but the cost is much more than twice. Disproportionately.

From this perspective, even if the product itself can be stacked and stored on the floor, or placed directly on the ground without using a pallet, it can be continuously increased. The load-bearing capacity of the ground must be taken into account. If the load-bearing range is exceeded, the stacking cannot be continued. .

2. Product features

Whether the outer packaging of the product is stable. Everyone in the supermarket should have seen diaper products, as well as washing powder. The large packaging of these products is usually not a cardboard box, but like a nylon bag, the surface is very slippery. A diaper product does not weigh much by itself, but if it is stacked on a pallet and then stacked and stored, 2 disks are almost the limit, because if the disk is stacked 3 layers, it is easy to collapse (the product itself is not sufficiently supportive) . There are also some products that cannot be stubble in stacking, which can also cause instability.

Whether the inner packaging of the product is deformed. There are also some boxed products, the storage requirements will be clearly marked, the maximum stacking storage height, the maximum stacking height of each disk. The reason for this reminder is that the main consideration is that the products in the inner packaging are easy to squeeze and change. For example, our common large bottle of shower gel or shampoo is the kind of pressing nozzle design. If the weight is too large, it will easily cause the mouth to be pressed. Deformation or even breaking, causing product leakage. There are also some bagged laundry detergent products, which are not sufficiently supportive.

Whether the batch of the product is large. Under normal circumstances, when the warehouse stores goods, some rankings are planned. Generally, only products with the same code and the same batch are stored in the same ranking to ensure first-in, first-out and higher operational efficiency. Then, if the stored products In the case of multiple varieties and multiple batches, assuming that the products of the same code and the same batch cannot be stacked on a whole disk, it is difficult for us to stack disk storage.

From this perspective, whether the outer packaging of the product is stable, whether the inner packaging is easily deformed, and the batch batch of stored goods will also affect the storage height of the product.

3. Warehouse height

In the design process of the warehouse, there are two heights, the first is the eaves height, and the second is the top height. The roof design of a warehouse is usually a slope roof, you can also understand it as a herringbone roof. The eaves height is the height from the eaves to the indoor floor; the ceiling height is easier to understand, the height of the top of the warehouse from the indoor floor.

In the storage process of the goods, there is another data to refer to-the light distance. That is, there must be a distance of at least 50 cm between the roof lighting and the maximum storage height of the goods. This distance is mainly for safety considerations.

Therefore, when designing the storage height of goods, at least these "three heights" need to be understood. In addition, if the roof also involves heating facilities, fire pipes, fire sprinklers, etc., it is also necessary to pay attention to leave a safe distance. Avoid the forklift driver from touching these facilities and causing unnecessary losses during operation.

ICP备案号:粤ICP备13050028号  粤公网安备 44030902000470号

粤公网安备 44030902000470号

COPYRIGHT© SHENZHENG XING NENG PLASTIC PRODUCTS CO.,LTD

Huaning road,dalang longhua district,4th Shenzheng Guangdong CHINA

The phone:+86-0755-15712136850

Welcome check our website:www.plastic-pallet.com.cn

E-MAIL:xnsujiao@foxmail.com

E-MAIL:Liuw55558@gmail.com

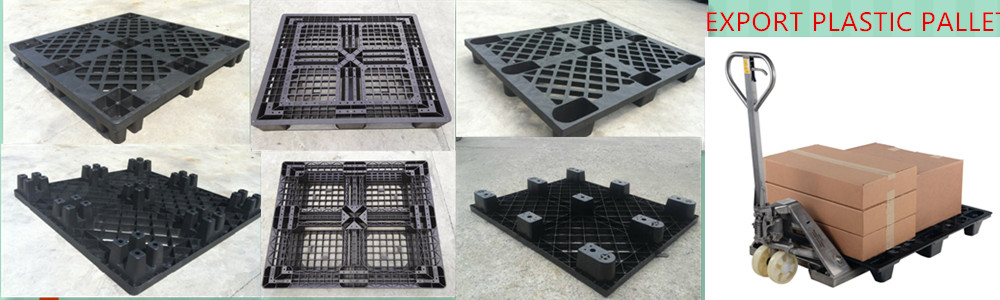

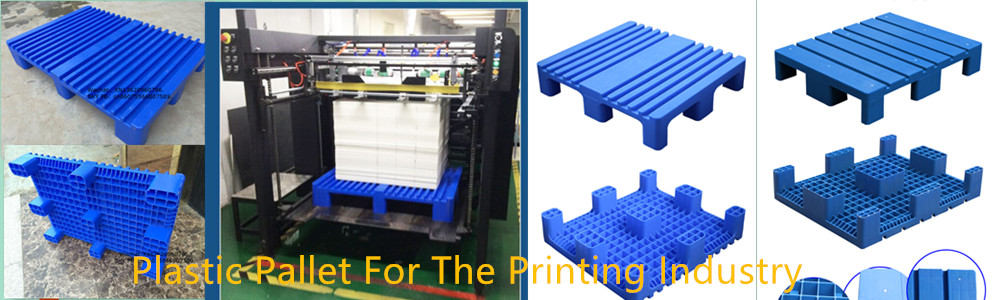

Plastic pallets · Half pallets · Euro pallets · Industrial pallets · Injection moulding plastic pallets · Reusable plastic pallets · HDPE plastic pallets · Recycled plastic pallets · Pallets made from regranulated material · Pallets made from regenerated material · 4 way entry pallets · Hygienic pallets · Cleanroom pallets · Haccp pallets · Closed deck plastic pallets · Heavy duty pallets · rfid pallets · Racking pallets · Conductive pallets · Perimeter base pallets · Custom made plastic pallets · Pallets with special dimensions · Special pallets.printing pallets.·Printing Pallets-Plastic Pallet Provider-Steel Pallets-Economy Pallets-Export Pallets